We make tubes of different diameters, with a greater number of thicknesses and different materials such as copper, stainless steel and cupronickel. The tube expansion, during the flaring phase, allows a perfect contact between the tubes and the fins and as a consequence it assures efficient thermal exchange.

COPPER – Copper tubes

Copper tubes from 0,3mm to 0,9mm thick are used according to the pressure exercised by the fluid on the exchanger.

| ø (MM) | Thickness (MM) |

|---|---|

| 7 | 0,27 |

| 9,52 | 0,28 / 0,30 / 0,35 / 0,41 / 0,70 / 0,90 |

| 12,7 | 0,35 |

| 15,88 | 0,38 |

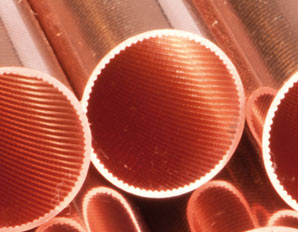

COPPER – Helically toothed copper tube

The helically toothed copper tubes guarantee greater thermal efficiency compared with plain tubes because they increase the surface area in contact with the fluid. Moreover, in this way the movement of the fluid inside the exchanger is increased thus increasing the exchange of heat.

| ø (MM) | Thickness (MM) |

|---|---|

| 7 | 0,28 × 0,15 |

| 9,52 | 0,28 × 0,15 |

| 12,7 | 0,35 × 0,25 |

© Picture: Wieland, Ulm, Germany

STAINLESS STEEL - AISI 316L TUBE

AISI 316L stainless steel tubes without welding are suitable for use in the food industry, in the medical sector and for use in marine environments; they are also resistant to the many corrosive substances used in the chemical industry.

Moreover, they offer the possibility of exploiting values of mechanical resistance that are greater than those of traditional materials.

| ø (MM) | Thickness (MM) |

|---|---|

| 9,5 | 0,5 |

CUPRONICKEL - CuNi10Fe1Mn Tube

Tubes in 90/10 Cupronickel are characterized by excellent resistance to corrosion in marine environments, considerable mechanical resistance to traction and to stress, very good resistance also to biofouling and to corrosion in a marine environment.

| ø (MM) | Thickness (MM) |

|---|---|

| 9,52 | 0,45 |